The Pharmaceutical Supply Chain and Radio-Frequency Identification

Add bookmarkRadio frequency identification is essentially an automatic data collection technology that uses radio waves to transfer data between a reader and a tag that catalogues, tracks, and continues to identify items fast and reliably without contact.

Radio-frequency identification (RFID) is a good method for two major issues with the pharmaceutical supply chain in the 21stcentury – counterfeited drugs and cold chain.

Radio Frequency Identification [RFID] was, through the 1990’s, embryonic and is now becoming nascent, in fact mushrooming since the millennium. During the past few years considerable improvement and expansion of the technology itself has been made leading to more applications that have taken advantages in achieving business effectiveness and competence.

The growing interest in telematics and mobile commerce will bring RFID even closer to all industries and consumers.

Today I will exam the RFID Data Capture’ of the cStar’sStealth RFID tags www.cstartech.com

The systems provides controlled, convenient 24/7 access to restrictive items held in a secure environment, wirelessly providing flexible networked connections at various locations and their extensions, including their in-house movement. cStar’s systems introduce inventory automation management with accurate statistical recorded data for further distribution allotment and ongoing dispersal allocation. The system eliminates support paperwork and older color-coded tags with barcodes that become smeared, smudged or badly soiled, dirty and torn making them unreadable; including human errors jumble as sometimes associated with manual recording. Within this systems design there are commonly interconnected long and short range pRFID [passive] Balun Designs that are matching but although larger correspond to those arrays used within freezer environments.

Counterfeited Products

There are many challenges facing the pharmaceutical industry of the 21st century. Patents on major drugs continue to expire, while companies struggle to produce innovative breakthroughs to offset the impact of generic substitutes. The regulative environment is becoming more intense.

There is much concern in the industry and from its large healthcare clients and their patients, about whether a drug that has been prescribed is authentic or not. This degree of authentication not only applies to getting the drug as described on the packaging from the company that produces the drug, but also covers ensuring that the drug dispensed has not come from an allocation made to the Third World or from repackaged out-of-date stock. The pharmaceutical industry estimates that between 2 and 7 percent of all drugs sold globally are counterfeit.

Cstar’s Brand Protection:

In domains requiring 'brand protection' such as the pharmaceutical industry they propose a method of applying a Stealth-Vigilant Tag strategically under the brand, trademark labelling; same applies also for serial number labels with device coded attachments.

In the USA, Canada and Europe, the commercial goods, pharmaceutical, biomedical industries experience product infiltration with unknown, non-genuine, imitation, after-market knock-offs. These knock-offs are then either knowingly or unknowingly sold to end users and consumers as authentic products, charging authentic prices.

Shows a medicine pharmaceutical bottle with both identification/intrusion Stealth Tag attachedaround the outer part of the lid or stopper

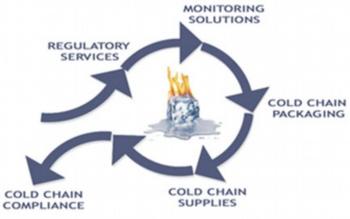

Cold chain

Life sciences products have grown more complex, and this complexity often increases product value — and sometimes — temperature sensitivity. Either outcome places a greater burden on cold chain professionals to reduce risk.

Temperature monitoring tags with RFID technology incorporates a sensor that captures the ambient temperature at specific intervals. Sensors are calibrated to detect high and/or low temperatures. Any temperature excursion triggers a visual indication on the tag and also records the temperature, date, and time.

Wireless capabilities allow workers to start, stop, or read the tags without opening boxes. Data from thousands of tags can be captured and reviewed on mobile readers before being downloaded to a PC. Traditional monitoring devices, in contrast, must be unpacked from boxes and taken to a PC for downloading. Report generation often occurs off-site, days later. As a result, RFID tags offer much faster data retrieval.

Another advantage of RFID temperature monitoring involves logistics, with its goal to save time and costs. The benefits of wireless data access, compact packaging, toughness, reusability, and streamlined handling and administration simplify temperature monitoring processes, reducing expense. In addition, RFID tags offer a low cost per use. More important, the logistical benefits favor widespread use of the devices for greater coverage and risk reduction.

[eventpdf]

cStar's TrakR and cStar eDispense

cStar's TrakR

cStar's TrakR series is an end-to-end, wirelessly-enabled system that tracks the

distribution of medical and life science products stored in freezers and refrigerators.

With cStar's TrakR solution, it is possible to store, refrigerate and distribute restricted products in an automated, secure, paperless environment, while remotely monitoring inventory and collecting accurate statistics on product use and sales. And TrakR's fail-safe early alarms means confidence that refrigeration units are functioning properly, storage temperatures are consistent and products are secure at all times.

With TrakR, it is possible to remotely monitor and manage every detail of the inventory and respondquickly to sales activity and product storage conditions to eliminate product shortages and product expiration, significantly boosting both operation efficiency and customer service. And TrakR supports activity-based accounting, so that it is possible to track products to projects, researchers and grants and maintain comprehensive records of end-user access and product distribution.

cStar's eDispense

cStar's eDispense system is a remote-monitored vending apparatus for life science products, including reagents, enzymes and controlled narcotics, which need to be stored in chilled or frozen environments. A wirelessly-enabled dispensing system, eDispense uses GPRS / GSM / ARDIS and MOBITEX wide area networks and Spread Spectrum local area networks to provide controlled, 24-hour access to products in a secure, paperless environment, providing authorized users with around-the-clock access to climate-sensitive and restricted medical and life science products, while automatically managing and tracking inventory, compiling accurate sales data and logging all machine activity.

Automated inventory and supply chain management eliminates the chance that a dispensing apparatus will sell-out of a crucial product when it's needed most. And the eDispense system's automated security function monitors machine temperatures and alerts administrators to temperature fluctuations and system errors in real-time - so eDispense users get the products they need, when they need them, in a secure, automated environment.

The Chinese were probably the first to use a form of RFID in the form of lodestones in the first century BC.It wasn’t until Harry Stockman’s landmark paper came along ‘Communication by means of Reflected Power’ in 1948, and at least 30-years would pass before Harry’s vision would begin to reach fruition and the major breakthrough came when Los Alamos presented ‘Short-range Radio-Telemetry for electronic identification using modulated backscatter’ in 1975.

(Courtesy of www.cstartech.com)

| Have Your Say Rate this feature and give us your feedback in the comments section below |